Mold Design

Crafting Precision, Shaping Perfection

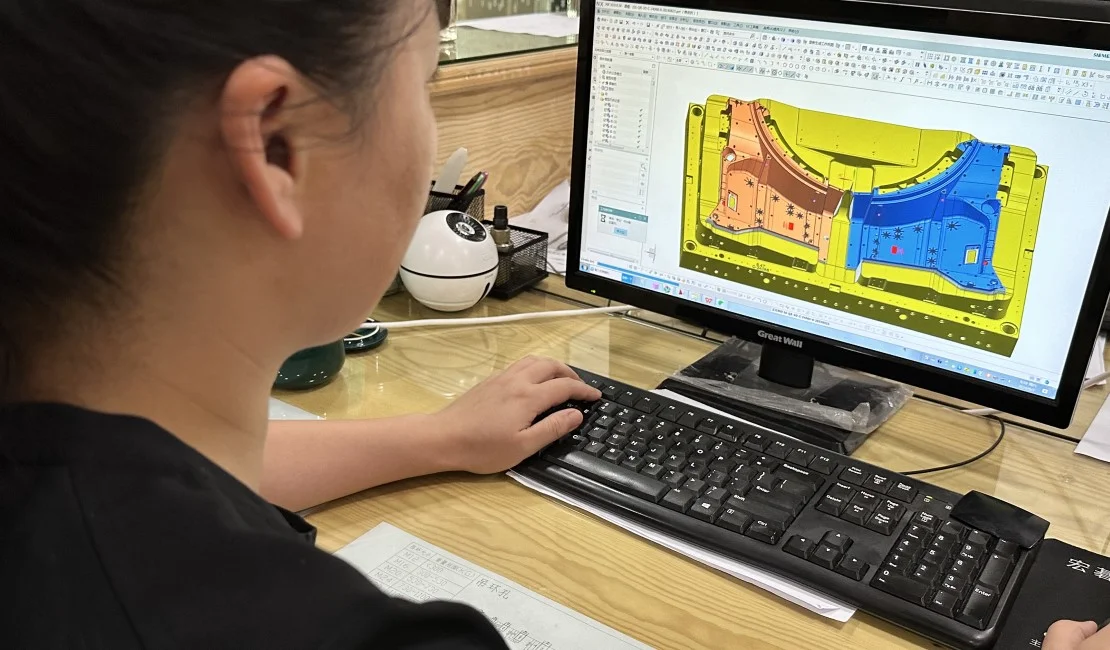

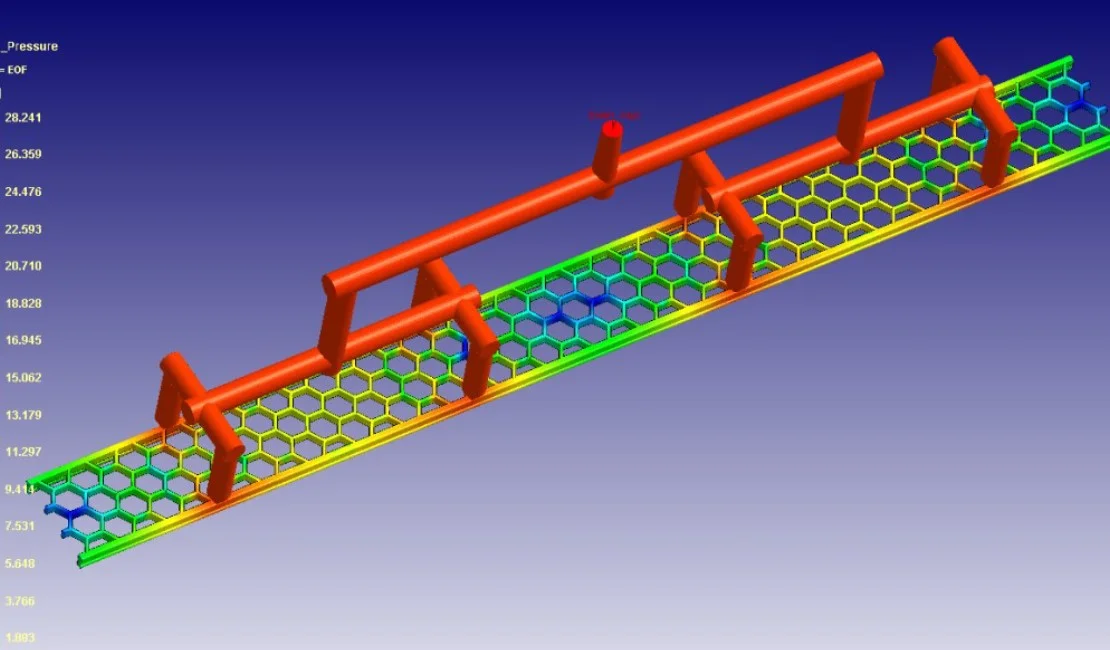

SANSE Group possesses outstanding technical capabilities in mold design. We utilize advanced Computer-Aided Design (CAD) and Moldflow analysis software to optimize mold runner layouts and cooling systems. We pay special attention to the wear resistance, thermal stability, and machining precision of molds to ensure their stability and efficiency during long production cycles. Our design team is proficient in various mold technologies, including hot runner molds, cold runner molds, and multi-cavity molds, to meet diverse production requirements in terms of complexity and volume.

With advanced technology and extensive experience in mold design, SANSE Group is committed to providing customers with efficient and precise mold solutions. We leverage modern design software and a top-notch technical team to ensure optimized mold designs and shortened development cycles.

Software and Technical Support

We employ leading CAD software such as UG, ProE, Parasolids, and SolidWorks for mold design and optimization. These tools not only support the modeling of complex geometries but also facilitate detailed mold flow analysis and thermal management simulations. By utilizing these advanced tools, we can accurately predict mold performance during the design phase, optimize design solutions, and reduce the need for later modifications, significantly shortening mold development cycles.

Design Team

Our mold design team consists of highly qualified engineers, ensuring the efficient execution of every project. The team structure is as follows:

● Chief Engineer: Responsible for overall design direction and solving technical challenges, ensuring that mold designs meet high standards and customer requirements.

● Group A Leader: Manages the mold design work for the first group, coordinating design tasks within the team and driving project progress.

● Group B Leader: Oversees the mold design work for the second group, ensuring design quality and progress meet expectations.

● 2D Mold Design Engineers (11): Focus on the design of two-dimensional mold drawings, ensuring the accuracy and operability of design documents.

● 3D Mold Design Engineers (15): Responsible for three-dimensional modeling and simulation analysis of molds, optimizing mold structure and functionality.

● Product Design Engineers (7): Specialize in the aesthetic and functional design of products, ensuring that products meet design specifications and usage standards.

Design Process

We adhere strictly to a structured design process for mold design, including requirements analysis, conceptual design, detailed design, sample testing, and optimization. Each design phase undergoes rigorous review and validation to ensure that molds exhibit high precision and reliability during production. We also incorporate virtual simulation technology during the design phase to predict the flow, pressure, and temperature of the molds, optimizing mold structure and cooling systems.

Continuous Improvement and Innovation

SANSE Group is dedicated to technological innovation and continuous improvement. We continuously track the latest trends in mold design technologies and materials development, maintaining our team's professional standards and technical leadership through regular training and technical exchanges. We actively seek customer feedback to continuously optimize designs and enhance service quality.

By leveraging advanced design software, a professional team, and a systematic design process, SANSE Group is capable of providing efficient and precise mold design services, helping customers achieve high-quality production goals.