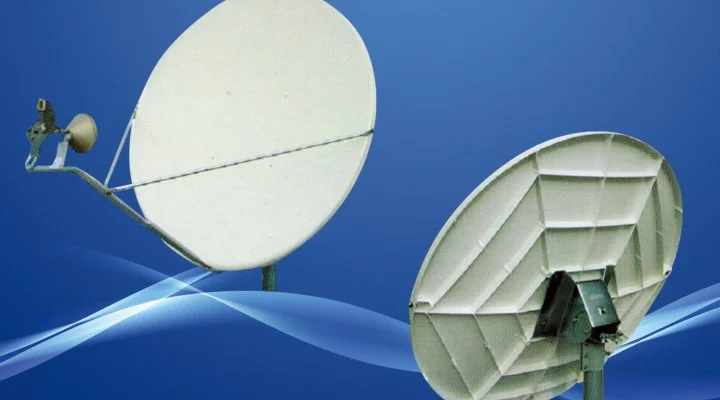

Satellite Antennas

Lightweight Connections, Boundless Communication

Five Key Advantages

Lightweight Design Reduces Weight

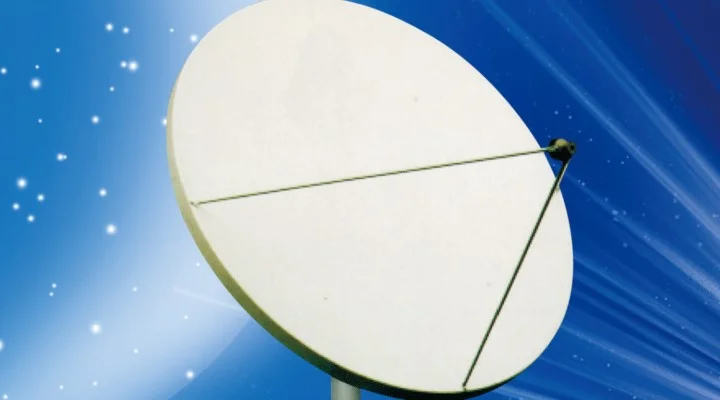

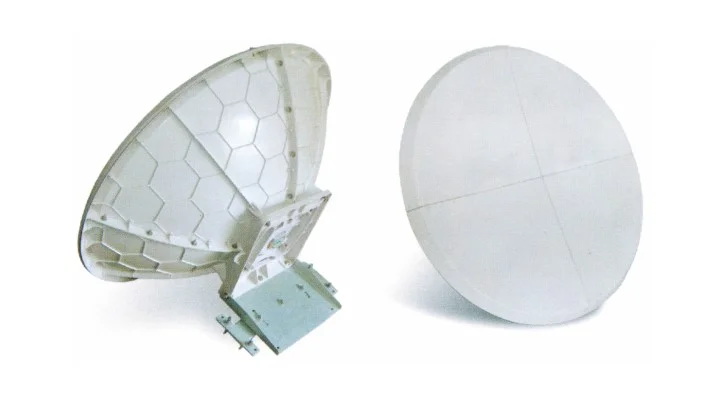

Composite materials such as SMC, PHC, and CF-SMC exhibit excellent lightweight characteristics, significantly reducing the overall weight of antennas. Compared to traditional metal materials, a lighter antenna can greatly lower transportation and installation costs while enhancing structural support efficiency, making them particularly suitable for demanding application scenarios like satellite communication and wireless transmission.

Exceptional Strength and Durability

These composite materials are not only lightweight but also possess high strength and impact resistance, ensuring that antennas can withstand harsh environments and resist damage from wind, rain, and snow. This high-strength characteristic is particularly advantageous for outdoor antennas and space exploration equipment.

Superior Electromagnetic Performance

Composite materials exhibit good electromagnetic transparency, reducing surface reflections and interference of electromagnetic waves, thereby enhancing signal transmission efficiency. This allows antennas to receive and transmit signals with greater precision, especially suited for high-frequency and high-bandwidth communication devices.

Corrosion Resistance and Aging Resistance

Compared to metal materials, composites offer strong corrosion resistance, capable of withstanding the erosion of acids, alkalis, and salt mist. Additionally, these materials exhibit excellent aging resistance, ensuring that antennas do not experience performance degradation or structural deformation after prolonged exposure to UV light, making them suitable for long-term outdoor use.

Cost Reduction through Integrated Molding

The compression molding process allows for the one-step formation of antennas, reducing complex assembly procedures and associated labor costs. By utilizing materials like SMC, PHC, and CF-SMC in the molding process, antenna manufacturing can achieve mass production and standardization, significantly increasing production efficiency while lowering costs and ensuring product consistency and high quality.

-

Lightweight Design Reduces Weight

-

Exceptional Strength and Durability

-

Superior Electromagnetic Performance

-

Corrosion Resistance and Aging Resistance

-

Cost Reduction through Integrated Molding

Development History

SANSE Satellite Antenna Division is one of the few leading companies in China specializing in the production of composite material satellite antennas. Leveraging advanced manufacturing processes, we employ a variety of compression molding technologies such as PUR-PHC, SMC, BMC, GMT, and LFT to produce high-performance satellite antenna products.

Since our establishment in 2007, we have continuously introduced cutting-edge global equipment and technology. With nine specialized hydraulic presses ranging from 315 tons to 2500 tons, we ensure large-scale production capacity. By integrating robotic automated drilling, cutting, and adhesive processes, we have significantly improved both production efficiency and product quality, providing our clients with high-precision, high-reliability antenna products and component processing services.

Our experienced and highly skilled R&D team uses professional software for antenna design and simulation analysis, perfecting each product solution. For different antenna project requirements, whether in terms of production volume, development cycle, or mold cost estimation, we can quickly formulate a plan. In the early stages of projects, we offer rapid prototyping for product validation or employ hand-laying techniques to flexibly meet diverse customer needs.

In 2008, we invested in a polyurethane composite production line dedicated to manufacturing lightweight portable satellite antennas. By utilizing carbon fiber and honeycomb materials in polyurethane composite integrated hot-press forming, we achieved high-strength, ultra-lightweight products, maintaining a leading position in this field domestically.

In 2013, we successfully launched an SMC sheet molding machine, further enhancing our price competitiveness in the fiberglass satellite antenna market. In 2016, we introduced RIM (Reaction Injection Molding) technology, expanding our business scope and overcoming technical barriers in antenna development.

To further enhance product precision and quality, in 2017, we added an optical scanner, allowing us to quickly detect products using high-precision inspection technology, ensuring continuous improvement and enhanced product quality.

As our technology advanced, in 2019, we deepened our partnerships with domestic and international suppliers, most notably signing a strategic agreement with Germany company Rühl Puromer, marking a significant step towards higher-level quality management.

To date, we maintain strategic partnerships with numerous clients in the satellite industry, both domestically and internationally. With our deep technical expertise and superior manufacturing capabilities in composite material antennas, the SANSE Satellite Antenna Division remains at the forefront of the industry, continuously driving the development of composite antenna products. We will continue to uphold the spirit of innovation, advancing our technology to provide superior solutions for our global clients.

Partner Clients