Rapid Prototyping

From Concept to Creation, Precision at Speed

Rapid prototyping technology is a crucial aspect of product development, enabling the swift transformation of design concepts into tangible models.

At SANSE Group, we employ various advanced technologies in rapid prototyping, including:

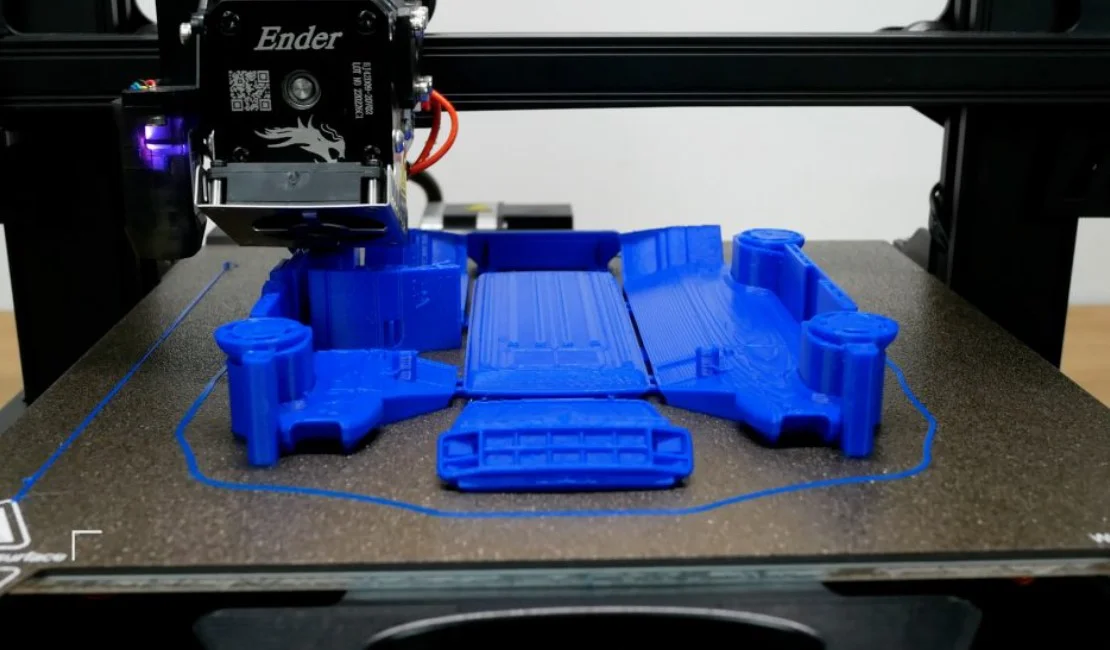

● 3D Printing (Additive Manufacturing): We utilize high-resolution 3D printing technology to create high-precision prototypes using a variety of materials, such as plastics, metals, and composites. 3D printing facilitates the rapid production of complex geometries and supports both single-piece and small-batch production requirements.

● CNC Machining: Precision cutting is achieved through Computer Numerical Control (CNC) machining, allowing us to effectively control the strength and dimensional accuracy of rapid prototyping components. We employ multi-axis CNC machining centers for efficient prototype manufacturing and functional testing.

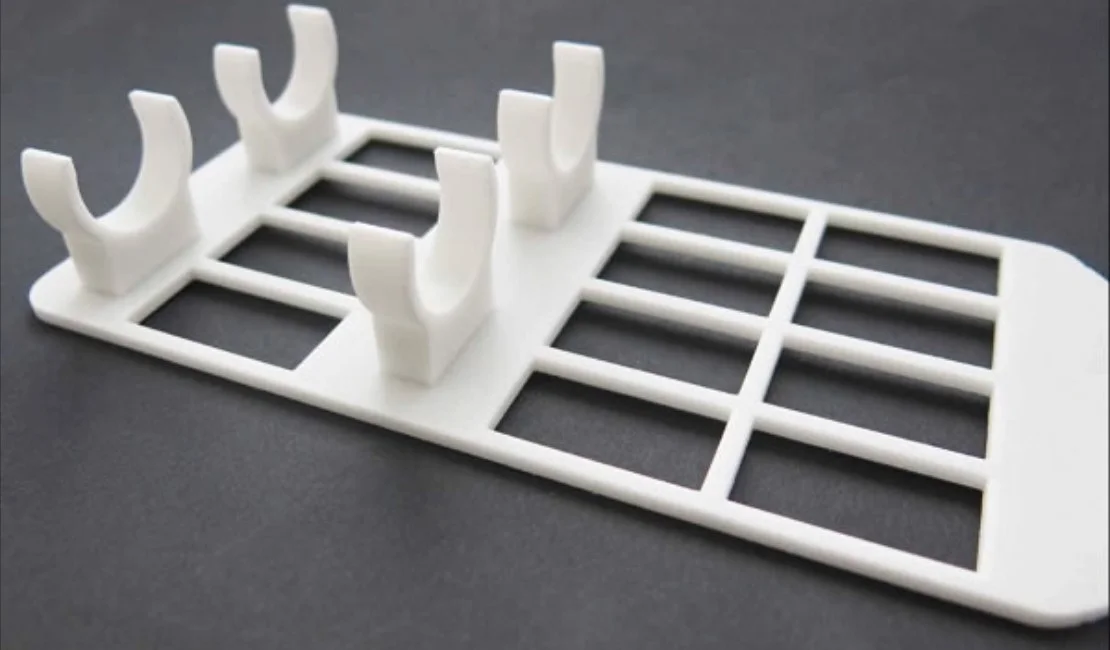

● Vacuum Casting: For prototypes that require high surface quality and precision, we utilize vacuum casting processes. This technique is suitable for silicone mold fabrication and can rapidly generate complex geometries with intricate surface finishes.

● Rapid Tooling: By leveraging digital manufacturing and rapid prototyping technologies, we can produce high-quality molds in a shorter timeframe for pilot production and product validation. This includes using aluminum alloys and composite materials as mold materials to expedite the production process.

● Soft Tooling: For clients needing small-batch pilot production, we manufacture soft tooling using cost-effective steel. This soft tooling is sufficient to support small-batch production of hundreds of units, allowing clients to validate their products and gather market feedback, which in turn informs the development of formal hard tooling.

These technologies enable us to quickly validate design concepts during the early stages of product development, thereby shortening development cycles and reducing costs.