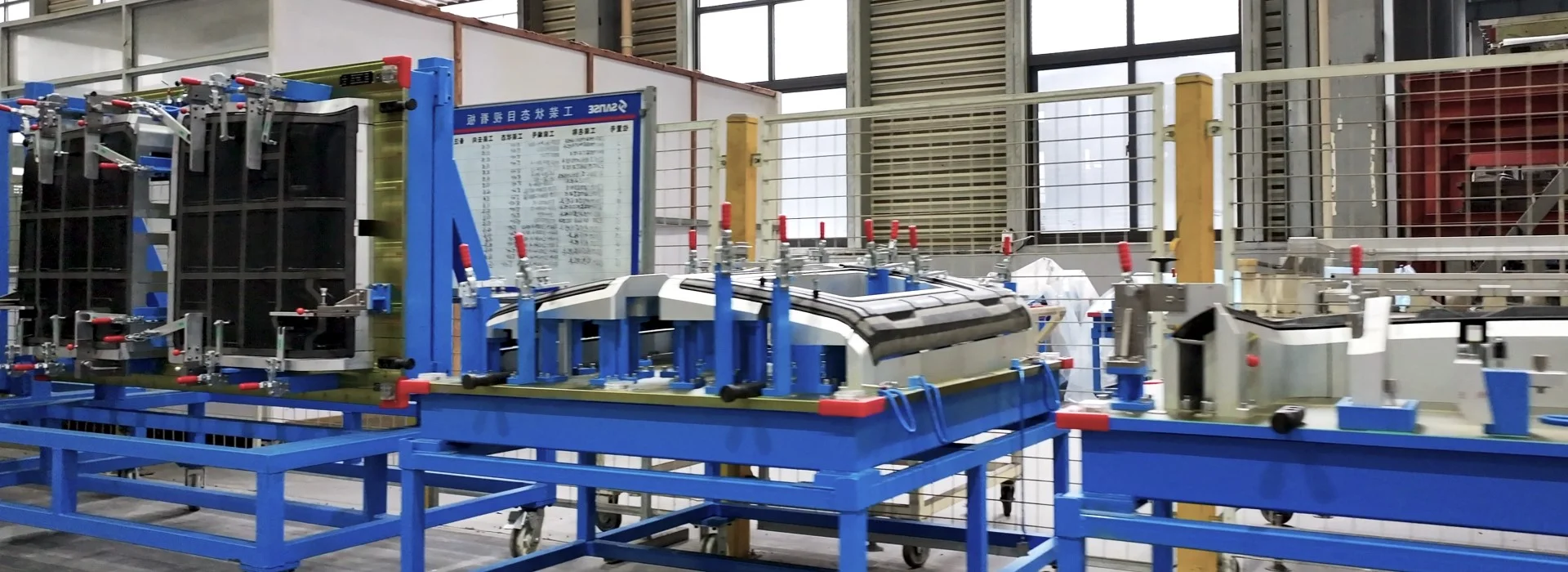

Tooling Manufacturing

Custom Tooling, Ensuring Seamless Production

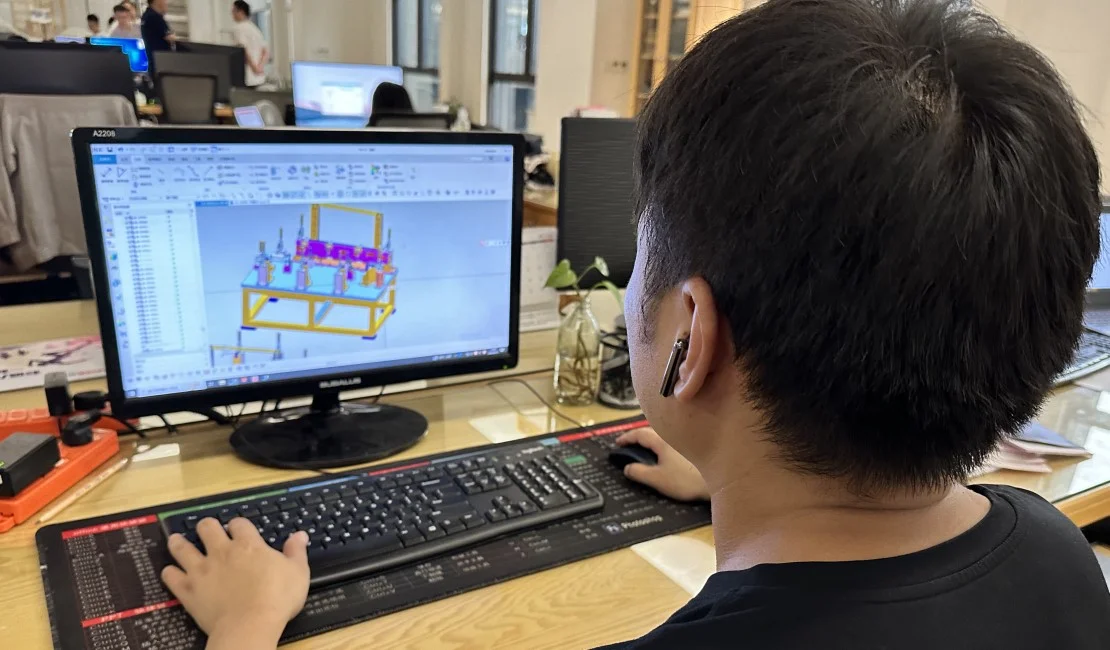

SANSE Group’s tooling manufacturing department focuses on the efficient design and production of specialized tools and fixtures. We utilize Computer-Aided Design (CAD) and Finite Element Analysis (FEA) for tooling design, ensuring stability and efficiency throughout the production process. Our tooling solutions include specialized fixtures, automated devices, and inspection gauges, aimed at increasing production line automation and ensuring product consistency. We place great emphasis on the durability and ease of maintenance of our tools to meet the demands of high-load and long-term production environments.

Types of Tooling and Applications

We design and manufacture various types of tooling to meet different production requirements, including:

● Cooling and Shaping Tools: Used for mold cooling and product shaping, ensuring precise product shape and stability during production.

● Cutting Tools: For precise cutting of composite materials, ensuring the accuracy of product dimensions and shapes.

● Drilling Tools: Used for high-precision drilling on products, supporting subsequent assembly and processing procedures.

● Bonding Tools: Used in bonding processes, ensuring uniformity and strength in product bonding.

● Assembly Fixtures: For use during product assembly, improving assembly efficiency and precision.

● Inspection Gauges: For checking and verifying product dimensions and quality, ensuring compliance with design specifications.

Technical Innovation and Quality

SANSE Group has earned the trust of clients with our rigorous design, simple operation, and safe, reliable tooling manufacturing capabilities. We continuously pursue technical innovation by integrating fully and semi-automated manufacturing processes to enhance both efficiency and quality. Our tooling designs not only emphasize functionality but also consider operational convenience and safety.

Project Experience

We have provided tooling solutions for several notable projects, including:

● Caterpillar Excavator Project: Designed and manufactured a series of high-difficulty shaping, cutting, and bonding tools, meeting stringent performance standards.

● Dongfeng Electric Car Project: Developed specialized tooling to support the production of electric vehicles, optimizing key processes in the production line.

● Jinan Sinotruk TGA (MAN Truck) Project: Designed and produced a series of high-precision shaping, cutting, and bonding tools for the TGA truck project, improving production efficiency and product quality.

Our Commitment

We are dedicated to providing our clients with the highest quality tooling manufacturing services. Through strict quality control and continuous technological improvements, we ensure that every tool we produce meets the needs of our customers and performs excellently in actual production. Our goal is to help clients achieve efficient, stable production processes through innovative tooling solutions.

With our professional tooling manufacturing capabilities and extensive project experience, SANSE Group is committed to offering reliable tooling solutions to support the smooth completion of complex production tasks.