Product Development

Innovative Designs, Driving Unmatched Excellence

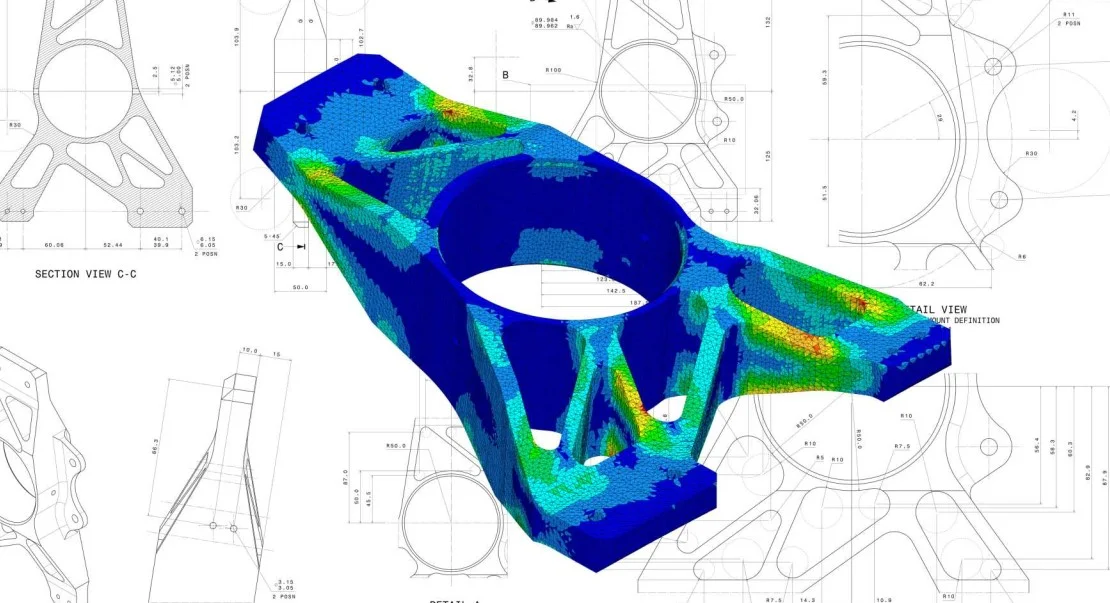

The Product Development Department at SANSE Group employs modern engineering design technologies to apply cutting-edge materials to practical products. We utilize Computer-Aided Design (CAD) and Finite Element Analysis (FEA) techniques for product design and performance simulation, ensuring that each design solution meets the highest standards of functionality and structural safety. Our development process encompasses everything from conceptual design and detailed engineering design to sample verification and optimization. By leveraging high-speed machining technologies and prototype manufacturing, we can rapidly iterate design solutions and conduct structural testing (such as static testing and dynamic fatigue testing) to validate product reliability and durability.

SANSE Group's Product Development Department is committed to applying advanced composite material technologies to real-world products, guided by the IDEAS system to drive innovation and ensure product quality. Our development process focuses not only on innovation but also on the comprehensive implementation of development, expertise, accountability, and standards.

I - Innovation

We continually explore and apply new technologies to drive product innovation. Through forward-looking materials research and design methodologies, we are dedicated to developing products with breakthrough performance. Our innovations include the application of new composite materials, the introduction of intelligent design tools, and the transformation of production processes to meet the growing demands of the market and our customers.

D - Development

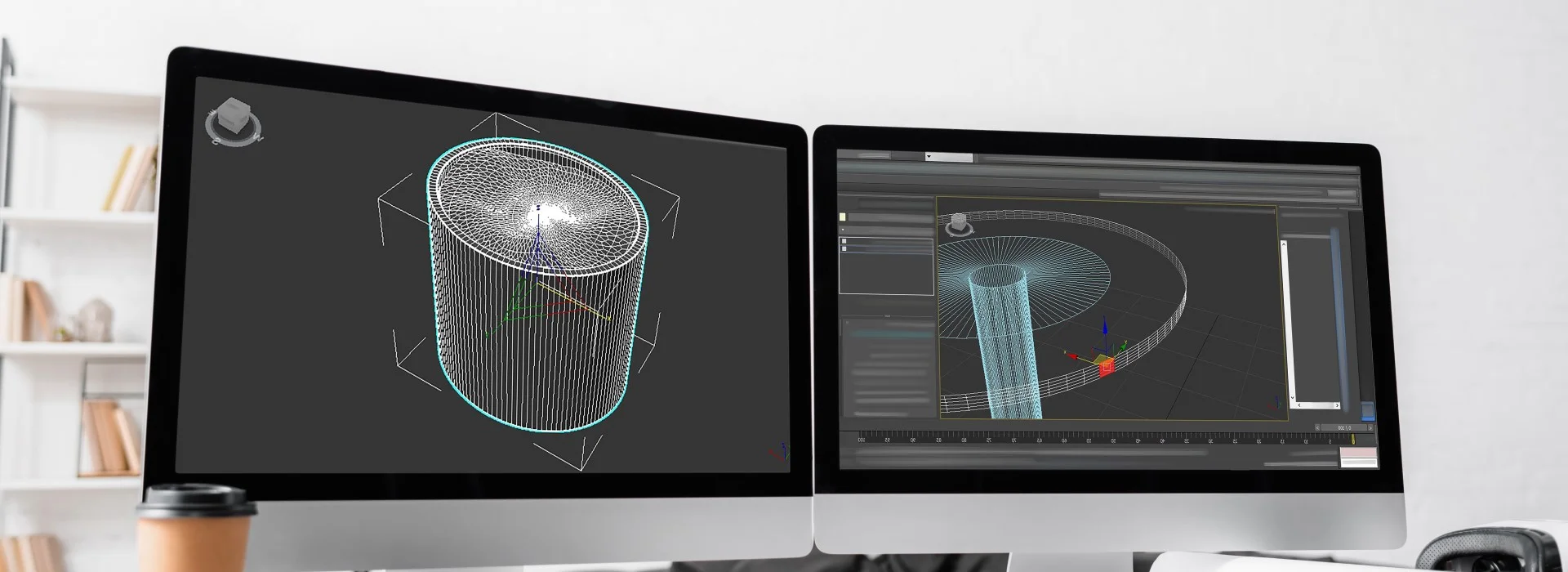

We employ advanced engineering technologies for product development, including CAD, FEA, and Virtual Reality (VR) simulation. Our development process begins with conceptual design, followed by detailed engineering analysis and sample production, leading to the final product's manufacturing. We focus on every design detail to ensure the performance and reliability of products in actual applications.

E - Expertise

SANSE Group boasts a highly qualified R&D team comprised of professionals from various fields, including materials science, engineering design, and manufacturing processes. We leverage extensive industry experience and deep technical expertise to provide professional technical support and solutions. Our team maintains sensitivity to cutting-edge industry technologies through continuous learning and training, ensuring that our products and technologies remain at the forefront.

A - Accountability

We take a high level of responsibility for every R&D project. Throughout the development process, we strictly adhere to project management best practices, ensuring timely delivery of products that meet high-quality standards. Our quality management system encompasses every phase, from design to production, ensuring that each product undergoes rigorous testing and validation to meet customer requirements and industry standards.

S - Standard

SANSE Group strictly adheres to international and industry standards in the product development process. We comply with ISO 9001 quality management system standards and ISO 14001 environmental management system standards, ensuring that our development processes and final products meet global quality and environmental requirements. We regularly review and update our design and manufacturing standards based on industry best practices to maintain exceptional product performance and consistency.

By implementing the IDEAS system, SANSE Group not only promotes product innovation and technological advancement but also ensures the efficiency and high quality of every R&D project. Our goal is to provide high-performance composite material products that meet customer needs through a systematic development process.

R&D Team Composition

? 113 total members

? Forward-looking R&D: 12

? Product Design: 29

? Mold Design: 20

? Material Development: 4

? Technical Processes: 30 (Injection Molding, Compression Molding, Painting)

? Project Managers: 18

Technical Capabilities

? From product design to mass production (CAD)

? Product FEA analysis and optimization

? GD&T capabilities

? FMEA & SPPC (Special Product and Process Characteristics)

? Verification plans and reports (DVP&R)

? Rapid response, benchmarking, and experience summaries

? Problem-solving capabilities (8D)

? Sample production and packaging

? Mold and tooling

? Manufacturing and process expertise

? Benchmark analysis

? Tolerance analysis

? Advanced technical research

R&D Software

? CATIA & UG/NX for internal design capabilities

o Comprehensive supplier design agreements

o Complete design provision and direct release for select OEM system clients

? Computer and engineering models:

o Hypermesh & Hyperview for preprocessing and postprocessing

o Optistruct for sensitivity analysis

o FiberSim for layup pattern optimization

o Mold Flow for flow analysis

? Minitab

? 2D tolerance analysis